The Conditionall Mobile Ball Valve Testing Unit is a portable solution designed for efficient on-site testing of ball valves. It provides real-time diagnostics, ensuring optimal valve performance and reliability. Ideal for industries like oil, gas, and power, this unit reduces downtime and maintenance costs. With advanced monitoring, it guarantees the integrity of critical valve systems.

The Conditionall Mobile Ball Valve Testing Unit is a portable device used to test ball valves on-site. It checks valve performance, detects leaks, and ensures they work properly. This unit saves time and money by avoiding the need to transport valves, making maintenance quicker and more efficient.

In this article, we will discuss “Conditionall Mobile Ball Valve Testing Unit”

Conditionall Mobile Ball Valve Testing Unit: A Detailed Overview

The Conditionall Mobile Ball Valve Testing Unit is a revolutionary solution designed to ensure the reliability and efficiency of ball valves used across various industries. This mobile, portable unit allows for quick and accurate testing of ball valves directly at the worksite, making it an indispensable tool for companies that rely on these valves for critical operations. Whether in the oil and gas sector, power plants, or chemical processing plants, this unit offers convenience, reduces operational downtime, and lowers maintenance costs.

Key Features of the Conditionall Mobile Ball Valve Testing Unit:

Portability:

One of the standout features of the Conditionall Mobile Ball Valve Testing Unit is its portability. The unit is designed for easy transport, enabling on-site testing of ball valves at any location. This eliminates the need for sending valves to off-site testing facilities, thus saving valuable time.

Real-Time Diagnostics:

The unit provides real-time data and diagnostics, giving immediate feedback on the condition of the valve. It can detect performance issues such as leaks, seat wear, and other irregularities, ensuring that valves are functioning properly before they cause any disruptions.

Efficiency and Cost-Effectiveness:

The mobile testing unit significantly reduces downtime by offering immediate results. This on-site testing capability eliminates the need to remove valves from their operating environment, reducing both transportation costs and labor time associated with repairs.

Also Read: Aluis Mobile Car Detailing – Mobile Car Detailing Services!

Advanced Technology:

Equipped with state-of-the-art sensors and technology, the unit offers detailed and accurate diagnostics. It tests various aspects of the valve, such as pressure resistance, flow rates, sealing performance, and more, to ensure the valve operates at peak efficiency.

Versatile Application:

The Conditionall Mobile Ball Valve Testing Unit is designed to accommodate a wide range of valve types and sizes, making it highly versatile. It is suitable for use in multiple industries, including oil and gas, chemical, water treatment, power generation, and more.

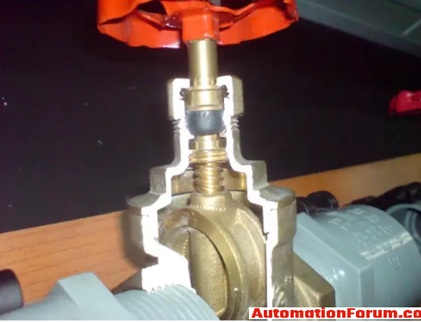

How the Conditionall Mobile Ball Valve Testing Unit Works?

The Conditionall Mobile Ball Valve Testing Unit is simple to operate yet highly effective in assessing ball valve performance. Here’s an overview of the testing process:

- Setup and Connection: The technician sets up the unit near the valve to be tested and connects it to the valve’s testing ports. These ports allow the unit to monitor critical parameters such as pressure and flow rate.

- Testing Process: After configuring the testing parameters, the unit begins its diagnostic procedure. The system tests the valve’s performance under various conditions to check for leaks, measure sealing strength, and assess any potential issues that could affect the valve’s operation.

- Results and Report: The Conditionall Mobile Ball Valve Testing Unit instantly processes the data and generates a comprehensive report. This report includes diagnostic results, performance insights, and any necessary recommendations for maintenance or repairs.

- On-Site Action: If minor issues are detected, the technician can often perform simple repairs or adjustments directly on-site, reducing the need for additional downtime or equipment transportation. More complex issues can be flagged for further attention.

Read: What is Fintechzoom – A comprehensive Guide of 2025!

Industries That Benefit from the Conditionall Mobile Ball Valve Testing Unit

Oil and Gas:

In the oil and gas industry, valves are critical for controlling the flow of fluids in pipelines and machinery. Ensuring that these valves are working correctly under high pressure is essential to prevent leaks or failures that could lead to hazardous situations or costly shutdowns.

Chemical Processing:

Ball valves in chemical plants handle highly reactive or corrosive substances, so maintaining their performance is crucial to avoid leaks that could lead to environmental or safety hazards. The mobile testing unit ensures these valves are operating as they should.

Also Read: Bank Mobile Customer Service – Bank Mobile Support!

Power Plants:

In power plants, valves control steam, water, and gas flows within boilers, turbines, and other equipment. The Conditionall Mobile Ball Valve Testing Unit ensures these valves are functioning correctly to prevent operational failures and keep the plant running efficiently.

Water Treatment:

Ball valves are also used in water treatment facilities to regulate water flow in filtration systems. Testing these valves ensures that the water supply is clean and consistent, maintaining public health and safety.

Benefits of Using the Conditionall Mobile Ball Valve Testing Unit:

- Time-Saving: The mobile unit allows for fast, on-site testing without the need to remove valves from their system. This quick turnaround minimizes downtime, which is critical in industries that rely on constant operations.

- Cost-Efficiency: By eliminating the need to transport valves to off-site facilities, the mobile testing unit cuts down on transportation and labor costs. Early detection of potential issues can also prevent expensive repairs or replacements in the future.

- Enhanced Safety: Ensuring that valves are working properly is essential for safety. The Conditionall Mobile Ball Valve Testing Unit helps identify potential hazards such as leaks or failures, reducing the risk of accidents and improving workplace safety.

- Proactive Maintenance: Regular testing of ball valves ensures that issues are caught early, enabling proactive maintenance rather than costly reactive repairs. This extends the life of the valves and helps maintain the efficiency of the entire system.

- Versatile and Reliable: Whether for routine maintenance or emergency repairs, the Conditionall Mobile Ball Valve Testing Unit is a reliable tool that can be used in diverse environments. Its versatility and dependability make it a must-have for companies looking to streamline valve testing and maintenance processes.

What is the standard test for ball valves?

The standard tests for ball valves include the shell test, which checks for leaks in the valve body, and the seat test, which verifies the seal between the ball and seat when closed. The valve is also subjected to an operational test to ensure smooth opening and closing. These tests follow standards like API 6D, ISO 5208, and ASME B16.34.

How do you test a ball valve?

To test a ball valve, perform a shell test to check for leaks in the valve body by applying pressure. Then, conduct a seat test to ensure there are no leaks between the ball and seat when the valve is closed. Finally, carry out an operational test to verify smooth valve operation and function.

What is the ASME standard for valve testing?

The ASME standard for valve testing is ASME B16.34, which covers the testing of valves for pressure, temperature, and leak integrity. It includes requirements for shell and seat leakage tests, as well as operational tests. The standard ensures that valves meet design, manufacturing, and performance criteria.

How to check valve quality?

To check valve quality, inspect the materials and construction for compliance with industry standards, such as ASME or API. Perform pressure and leakage tests (shell and seat tests) to ensure no leaks and proper sealing. Finally, verify smooth operation by cycling the valve and checking for any issues with movement or functionality.

What is the ISO standard for valve testing?

The ISO standard for valve testing is ISO 5208, which outlines procedures for pressure testing of valves, including shell and seat leakage tests. It specifies test pressures, durations, and acceptable leakage rates to ensure valve integrity and performance. This standard ensures valves et safety and reliability requirements.

How are ball valves measured?

Ball valves are measured by their nominal size, typically denoted in inches or millimeters, which refers to the valve’s internal diameter. The end connections are also measured, including flange, threaded, or socket weld sizes. Additionally, the pressure rating and temperature range are important factors for determining the valve’s specifications.

What is the British standard for ball valves?

The British standard for ball valves is BS 5351, which specifies the design, materials, testing, and performance requirements for industrial ball valves. It covers valve types with different end connections, including flanged, threaded, and welded. This standard ensures the valve meets safety, quality, and durability criteria for various applications.

FAQ’s

1. What is the Conditionall Mobile Ball Valve Testing Unit?

The Conditionall Mobile Ball Valve Testing Unit is a portable device for on-site testing of ball valves, ensuring optimal performance and reliability by detecting leaks and assessing valve condition.

2. How does the Conditionall Mobile Ball Valve Testing Unit work?

The unit connects to the valve’s testing ports, performs diagnostic tests, and generates a detailed report, helping detect issues like leaks and performance irregularities.

3. What are the benefits of the Conditionall Mobile Ball Valve Testing Unit?

It saves time and costs by providing on-site testing, reducing downtime, and enabling proactive maintenance to avoid costly repairs.

4. What is the standard test for ball valves?

The standard tests include the shell test for leaks in the valve body, the seat test to check the seal, and an operational test for smooth valve function.

5. What is the ISO standard for valve testing?

The ISO 5208 standard outlines pressure testing procedures for valves, including shell and seat leakage tests, to ensure valve integrity and performance.

Conclusion

In conclusion, the Conditionall Mobile Ball Valve Testing Unit is a valuable tool for industries that rely on ball valves for critical operations. Its portability and real-time diagnostics allow for on-site testing, reducing downtime and maintenance costs. By providing quick, accurate results, the unit ensures valve performance and safety, making it an essential solution for improving operational efficiency and reducing unexpected failures.

I’m Arlo Liam, and I bring over 10 years of hands-on experience in the mobile technology field. My journey in mobile technology has been driven by a passion for innovation, usability, and the evolving digital landscape.

From understanding the inner workings of smartphones to exploring emerging trends in mobile software and app development, I am committed to sharing in-depth insights and practical knowledge with users of all levels.