Printed Circuit Board (PCB) assembly is the backbone of modern electronics. Every gadget, device, and appliance we use today depends on this intricate process to function seamlessly. Whether it’s your smartphone, smartwatch, or even medical devices, PCB assembly ensures these technologies come to life. In this detailed guide, we’ll dive deep into what PCB assembly entails, how it works, and why it’s critical for innovation.

What is PCB Assembly?

PCB assembly refers to the process of placing and soldering electronic components onto a bare PCB to create a functional circuit board. Think of the PCB as a blank canvas and the components as the colors used to create a masterpiece. While PCB fabrication involves creating the physical board with its copper traces and layers, assembly focuses on bringing that board to life by integrating components such as resistors, capacitors, and microchips. It is this step that transforms a passive structure into an active, working part of an electronic device.

Overview of Printed Circuit Boards (PCBs)

Types of PCBs

- Single-layer PCB: Simplistic and cost-effective, used in low-end applications like toys and calculators.

- Multi-layer PCB: Consists of multiple layers of conductive materials, enabling complex designs like those in smartphones and computers.

- Rigid vs. Flexible PCB: Rigid boards offer durability, while flexible PCBs are ideal for wearable devices and products requiring folding or bending.

Components of a PCB

A PCB houses various components, each with a specific role in the circuit. These include:

- Resistors to control the flow of current.

- Capacitors to store and release electrical energy.

- Integrated Circuits (ICs) for complex functions.

- Connectors to interface with other systems or devices.

Applications of PCBs

PCBs are at the heart of countless industries. They power everyday gadgets, medical equipment, aerospace systems, automotive electronics, and more. Without PCBs, the technological advancements we enjoy today would not be possible.

Types of PCB Assembly Techniques

SMT is a revolutionary method where components are mounted directly onto the PCB surface without requiring holes. This method allows for compact designs and is widely used in modern electronics like smartphones, laptops, and IoT devices. The efficiency and precision of SMT make it the preferred choice for mass production. THT involves inserting component leads into drilled holes on the PCB and soldering them in place. While this technique is more labor-intensive, it provides robust mechanical bonds, making it ideal for applications requiring high durability, such as military and aerospace systems. In some cases, a combination of SMT and THT is used. For instance, devices that need both miniaturization and mechanical strength, like certain automotive electronics, rely on mixed technology assembly.

Key Steps in PCB Assembly

Design and Prototyping: The process begins with designing the circuit layout and creating a prototype. Engineers use software tools to design schematics and simulate the circuit’s functionality. Prototyping helps identify any flaws before full-scale production.

Solder Paste Application: A stencil printer is used to apply solder paste to specific areas of the PCB where components will be mounted. The paste contains tiny particles of solder mixed with flux, which helps form strong electrical connections during the soldering process.

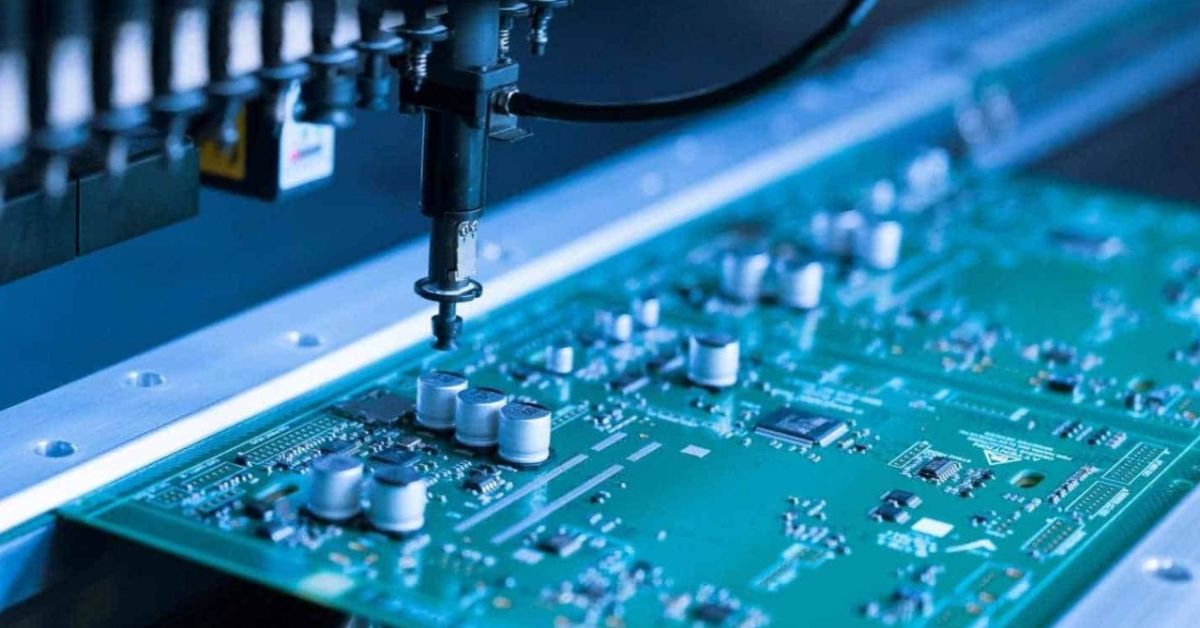

Pick-and-Place Process: Automated pick-and-place machines place components onto the PCB with incredible accuracy. These machines use high-speed cameras and advanced algorithms to ensure each component is positioned correctly.

Reflow Soldering: The PCB, now populated with components, passes through a reflow oven. The heat melts the solder paste, creating secure bonds between the components and the PCB.

Inspection and Quality Control: Quality control is crucial to ensure functionality and reliability. Automated Optical Inspection (AOI) systems, X-ray machines, and manual checks are used to identify and rectify defects such as misaligned components or soldering issues.

Functional Testing: The final step involves testing the PCB under real-world conditions to ensure it meets design specifications. Any failures at this stage are corrected before the product is shipped.

Importance of Quality Control in PCB Assembly

Quality control is not just a step; it is the backbone of the entire PCB assembly process. Defective PCBs can lead to device malfunctions, costly recalls, and even safety hazards. To mitigate risks, manufacturers employ advanced testing techniques like In-Circuit Testing (ICT) and Boundary Scan Testing. These methods detect issues such as short circuits, open connections, and incorrect component placements.

Challenges in PCB Assembly

As electronic devices become smaller and more complex, PCB assembly faces several challenges:

- Miniaturization: Shrinking components require precise handling and advanced equipment.

- Reliability: Ensuring PCBs work reliably in harsh conditions is critical for industries like aerospace and automotive.

- Design Complexity: Multi-layer PCBs with intricate layouts demand sophisticated assembly techniques.

Latest Trends in PCB Assembly

Automation, powered by artificial intelligence, is streamlining the assembly process. AI-driven machines can predict defects, optimize production lines, and reduce human errors, enhancing overall efficiency. With environmental regulations tightening, lead-free soldering is becoming the industry standard. This shift not only benefits the environment but also improves worker safety. As demand for high-speed communication grows, high-frequency PCBs are gaining popularity. These PCBs support advanced applications like 5G networks and radar systems.

Conclusion

PCB assembly is an indispensable part of modern electronics, transforming bare boards into functional powerhouses. As technology advances, the processes, techniques, and materials used in PCB assembly continue to evolve, enabling innovations that shape our world. Whether you’re a tech enthusiast, engineer, or business owner, understanding PCB assembly offers insights into the marvels of electronic manufacturing.

If you read more interested like PCB assembly, Please Visit our website agtalk.

I’m Arlo Liam, and I bring over 10 years of hands-on experience in the mobile technology field. My journey in mobile technology has been driven by a passion for innovation, usability, and the evolving digital landscape.

From understanding the inner workings of smartphones to exploring emerging trends in mobile software and app development, I am committed to sharing in-depth insights and practical knowledge with users of all levels.